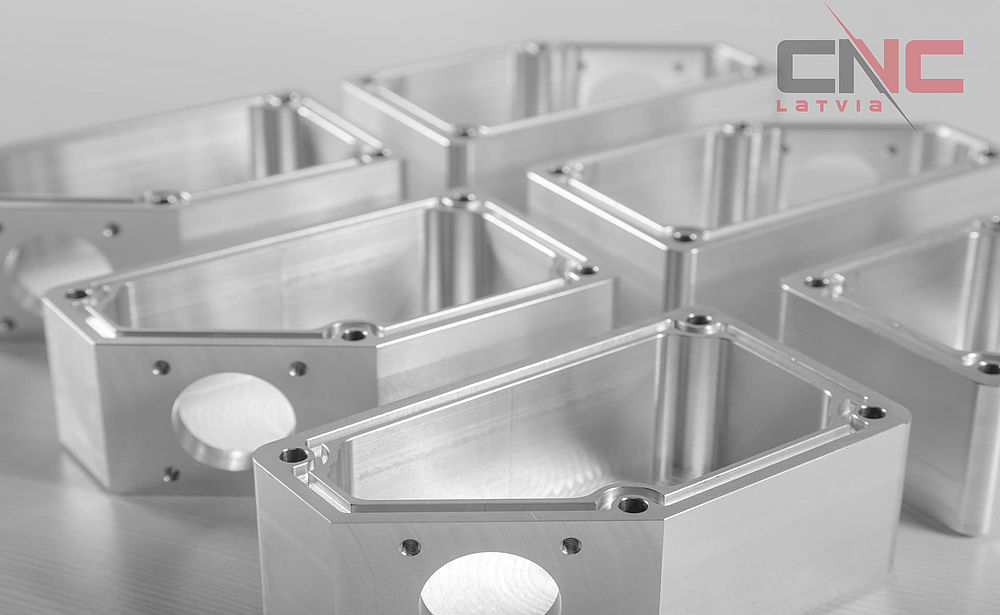

CNC milling

We produce parts from:

- Aluminum

- Steel

- Stainless steel

- Cast iron castings

- Steel forgings

- Bronze, brass

- Plastic

- etc

Product photo gallery > >

We offer:

- Milling parts of complex shape.

- Minimum part size 10 × 10 mm.

- Bulky (large) part milling: 1501 × 632 mm.

- Precision till 0.001 mm.

- Identical product repeatability in mass production.

- Capacity up to 10 000 parts a week.

Basic facts about CNC milling

Most people do not know what CNC milling is, however, our everyday comfort and well-being depends on this very technology.

CNC milling is a computer-aided machining of solid materials by cutting, which is carried out on program-controlled machines.

Medicine, mechanical engineering, food processing, new technologies — precisely produced parts are necessary in every industry.

The milling equipment’s cutting tool rotates around its axis at speed up to 12,000 rpm, machining a moving blank that is in the feeder.

Just like a sculptor turns a stone block into a sculpture, the milling machine cuts off excess material from the workpiece at various angles, till a final product is achieved according to the drawing.

Computer numerical control (CNC) allows to reach a completely new level of excellence in milling.

The program-controlled milling machine is able to perform much more complex operations than a manually operated mill, in much shorter time and with a precision to just few microns.

The CNC milling machine operates in 3–5 axes, providing unlimited possibilities of machining the material.

It easily handles fine operations that cannot be completed using a manually operated milling cutter — internal T-shaped milling, complex internal drilling and external profiles.

The milling surface can be flat, angular or arched.

We carry out CNC milling on Okuma multifunctional milling machines using high quality cutting tools from Seco and Sandvik. Machines are individually programmed for each order to ensure quality and that all parts are identical.

Our produced parts can be found in a wide variety of devices — from high sensitivity microphones to port cranes.

The excellence of CNC Latvia’s performance is guaranteed by a quality control system certified in accordance with the international standard ISO 9001:2015.