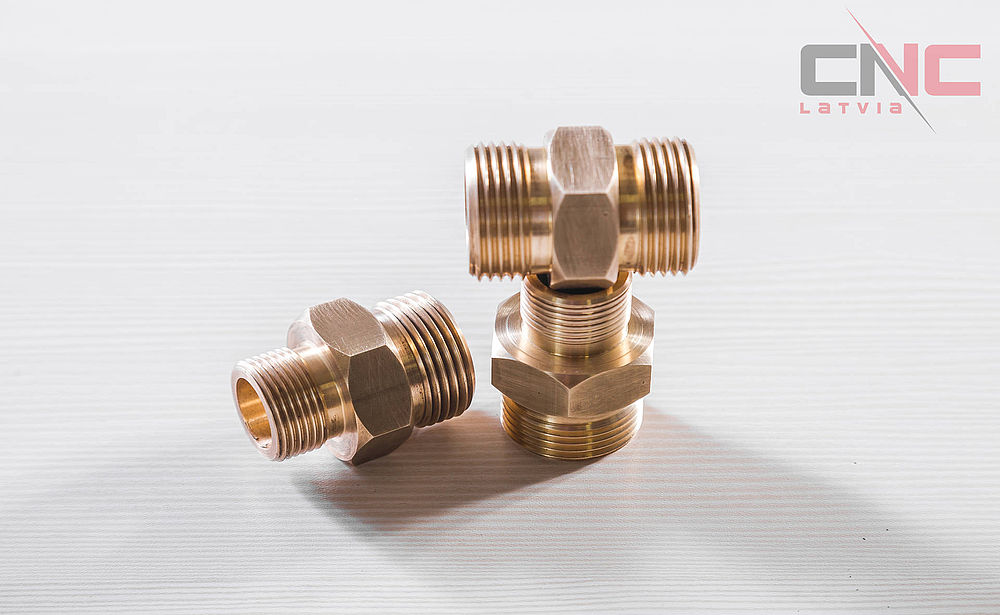

CNC turning

We produce parts from:

- aluminum

- steel

- stainless steel

- textolite

- plastic

- POM

- teflon (PTFE)

- etc.

We offer:

- Turning parts of complex shape.

- Machining diameter from 8 to 400 mm.

- Precision till 0.001 mm.

- Identical product repeatability in mass production.

- Capacity up to 10 000 parts a week.

Basic facts about CNC turning

Turning is the most well-known type of metalworking, creating products that accompany us every step of the way — from the most common screws to the rotating parts in complex mechanisms.

Cutting and rotation (turning) are the very two things on which the turning process depends: a lathe cuts the product that rotates around its axis at high speed (up to 3500 rpm).

Turning is used to treat both metal and other materials such as plastic and Teflon.

Computer numerical control (CNC) elevates turning to a new quality level, increasing several times the machining speed and precision.

Software-controlled turning machines perform both external and internal surface treatments — turning, drilling, grating, threading, etc.

A CNC lathe allows to machine parts which a manually controlled lathe cannot handle, such as — conical thread, a 2-3-step thread, etc.

The whole process is controlled by a computer program, while the main task of the machine operator is the quality control.

CNC turning is the best solution when the needed part cannot be freely bought — contact us for a commercial offer.

We carry out CNC turning on Okuma lathes using high quality new generation cutting tools from Seco and Sandvik.

Machines are individually programmed for each order to ensure quality and that all parts are identical.

Our products can be found in a wide variety of devices — from high sensitivity microphones to port cranes.

The excellence of CNC Latvia’s performance is guaranteed by a quality control system certified in accordance with the international standard ISO 9001: 2015.